The Stuff Box In A Paper Mill: Your Ultimate Guide

Let’s dive right into it, shall we? If you’re reading this, chances are you’ve stumbled upon the mysterious world of paper mills and are curious about something called the “stuff box.” Don’t worry, you’re not alone. The stuff box might sound like a plot device in some sci-fi movie, but trust me, it’s a critical player in the paper-making process. In fact, without the stuff box, the entire operation might just fall apart. So, buckle up, because we’re about to unravel its secrets.

Now, I know what you’re thinking—“Why does a simple box deserve so much attention?” Well, my friend, the stuff box isn’t just any box. It’s the heart of the paper-making process, where all the magic happens before the paper actually takes shape. Think of it as the mixing bowl in your kitchen, except instead of flour and eggs, it’s filled with pulp, water, and a bunch of other ingredients that eventually become the paper you use every day.

So, why are we even talking about this? Because understanding the stuff box can give you a deeper appreciation for how paper is made. And let’s be honest, in a world where we’re constantly surrounded by digital screens, there’s something comforting about knowing how the tangible stuff around us comes to life. So, without further ado, let’s get started!

Read also:Ultimate Guide To Brazilian Wax In Moreno Valley Ca Everything You Need To Know

What Exactly is the Stuff Box?

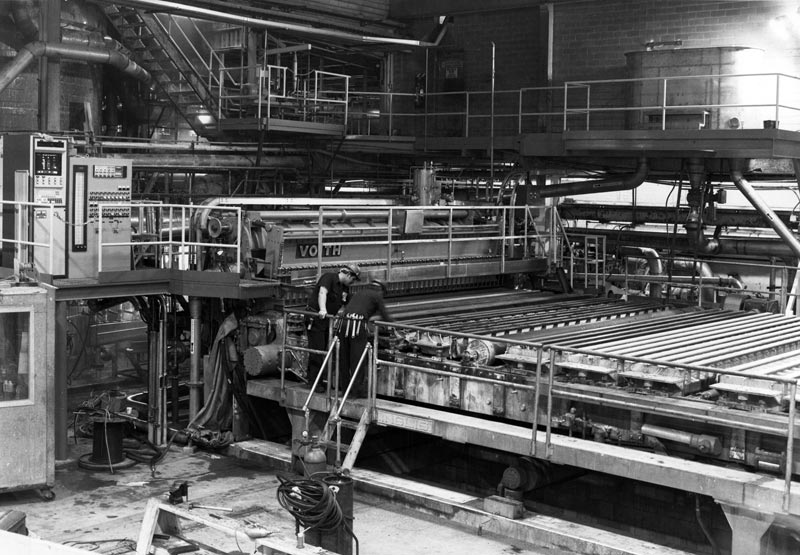

Alright, let’s break it down. The stuff box is essentially a large container used in paper mills to store and prepare pulp before it’s turned into paper. But it’s not just a glorified storage tank—it plays a crucial role in ensuring the pulp is evenly mixed and ready for the next steps in the paper-making process. Think of it as the prep area where everything gets perfectly blended before hitting the production line.

Here’s the deal: the stuff box holds the pulp mixture, which is a combination of water, wood fibers, and sometimes additives like dyes or fillers. This mixture is carefully controlled to ensure the right consistency and quality, which ultimately affects the final product. And no, it’s not as simple as throwing everything into a blender and calling it a day. There’s a lot of science and precision involved.

Why is the Stuff Box Important?

Let me tell you, the stuff box isn’t just important—it’s essential. Without it, the pulp wouldn’t be evenly mixed, and the paper produced would be inconsistent in quality. Imagine printing out a document only to find that half the page is thicker than the other half. Not ideal, right? That’s where the stuff box comes in to save the day.

Here’s why it matters:

- It ensures the pulp mixture is consistent throughout the batch.

- It allows for adjustments to be made before the pulp moves to the next stage.

- It helps maintain the quality and thickness of the final paper product.

In short, the stuff box is like the conductor of an orchestra, making sure everything is in harmony before the big performance.

How Does the Stuff Box Work?

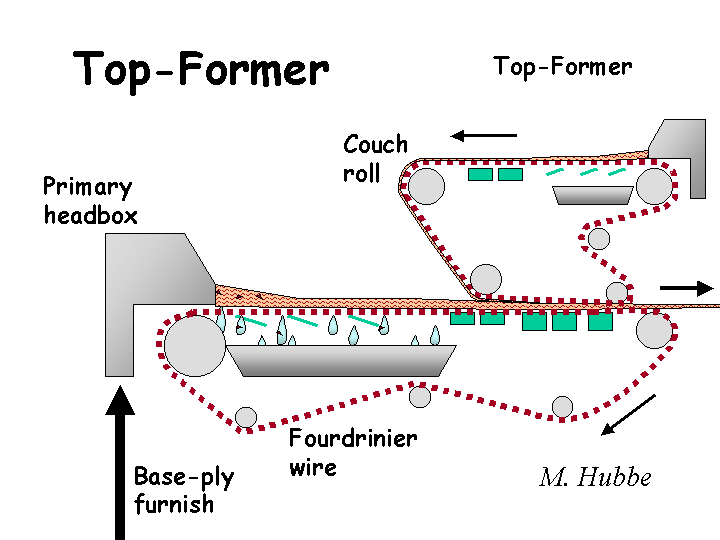

Now that we know what the stuff box is, let’s talk about how it works. Picture this: the pulp mixture flows into the stuff box from the pulping process. Inside the box, the mixture is agitated and circulated to ensure it’s evenly mixed. This is where the magic happens—well, not really magic, but you get the idea.

Read also:Smedium Senegalese Twist The Ultimate Guide To Achieving Gorgeous Twists

The stuff box is equipped with various mechanisms to keep the pulp moving and prevent it from settling at the bottom. This is crucial because if the pulp settles, it can lead to uneven distribution and, ultimately, poor-quality paper. So, the stuff box is constantly working behind the scenes to keep everything smooth and consistent.

Key Components of the Stuff Box

Let’s take a closer look at the key components that make the stuff box tick:

- Inlet Pipes: These pipes bring the pulp mixture into the stuff box from the pulping process.

- Agitators: These are the mechanisms that keep the pulp moving and prevent settling.

- Outlets: Once the pulp is mixed and ready, it flows out of the stuff box to the next stage of the process.

These components work together to ensure the pulp is perfectly prepared for the next steps in the paper-making process. It’s like a well-oiled machine, with each part playing its role to perfection.

Types of Stuff Boxes

Not all stuff boxes are created equal. Depending on the type of paper being produced and the specific needs of the mill, different types of stuff boxes may be used. Here are a few common types:

1. Horizontal Stuff Boxes

These are the most common type of stuff boxes and are typically used for producing standard paper products. They’re designed to handle large volumes of pulp and ensure consistent mixing.

2. Vertical Stuff Boxes

Vertical stuff boxes are often used in smaller mills or for producing specialty papers. They’re more compact and can be easier to maintain, but they may not handle as large a volume as their horizontal counterparts.

3. Pressurized Stuff Boxes

Pressurized stuff boxes are used when a higher level of control is needed over the pulp mixture. They can help achieve more precise consistency and are often used in the production of high-quality paper products.

Each type of stuff box has its own advantages and is chosen based on the specific requirements of the mill and the paper being produced.

Common Challenges in Using the Stuff Box

Of course, nothing is perfect, and the stuff box is no exception. There are a few common challenges that paper mills may face when using the stuff box:

- Settling: If the pulp isn’t properly agitated, it can settle at the bottom of the box, leading to uneven mixing.

- Overflow: If the stuff box is overfilled, it can lead to overflow, which can disrupt the entire production process.

- Maintenance: Like any piece of equipment, the stuff box requires regular maintenance to ensure it’s functioning properly.

These challenges can be mitigated with proper training, regular maintenance, and the use of advanced technology to monitor and control the process.

Advancements in Stuff Box Technology

Technology is always evolving, and the stuff box is no exception. Modern stuff boxes are equipped with advanced sensors and automation systems that allow for real-time monitoring and control of the pulp mixture. This means mills can achieve even greater precision and consistency in their paper production.

Some of the latest advancements include:

- Smart Sensors: These sensors can detect changes in the pulp mixture and automatically adjust the agitation and flow rates.

- Automation Systems: These systems can control the entire process from start to finish, ensuring consistent quality and reducing the need for manual intervention.

- Data Analytics: Mills can now use data analytics to optimize their processes and identify areas for improvement.

These advancements not only improve the efficiency of the paper-making process but also help reduce waste and environmental impact.

The Role of the Stuff Box in Sustainable Paper Production

In today’s world, sustainability is a top priority for many industries, including paper production. The stuff box plays a crucial role in this effort by helping mills achieve greater efficiency and reduce waste. By ensuring the pulp mixture is evenly mixed and consistent, the stuff box helps minimize the need for additional processing and reduces the amount of water and energy used in the production process.

Additionally, modern stuff boxes are designed to handle recycled pulp, which is becoming increasingly important as more mills adopt sustainable practices. This allows for the production of high-quality paper products while minimizing the environmental impact.

Environmental Benefits of the Stuff Box

Here are a few ways the stuff box contributes to sustainable paper production:

- Reduces water usage by ensuring efficient mixing.

- Minimizes energy consumption through advanced automation.

- Supports the use of recycled materials in paper production.

By focusing on sustainability, paper mills can not only reduce their environmental footprint but also appeal to environmentally conscious consumers.

Future Trends in the Stuff Box Industry

So, what’s next for the stuff box? As technology continues to evolve, we can expect even more advancements in the way stuff boxes are designed and used. Some potential trends include:

- Increased Automation: More mills will adopt fully automated systems to streamline the paper-making process.

- Sustainable Materials: The use of sustainable materials in the construction of stuff boxes will become more common.

- Artificial Intelligence: AI will play a larger role in monitoring and optimizing the performance of stuff boxes.

These trends will not only improve the efficiency of paper production but also help mills stay competitive in an ever-changing market.

Conclusion

And there you have it—the ultimate guide to the stuff box in a paper mill. From its role in the paper-making process to the latest advancements in technology, the stuff box is a fascinating piece of equipment that plays a crucial role in producing the paper we use every day.

So, the next time you pick up a piece of paper, take a moment to appreciate the journey it took to get there. And remember, it all started with the humble stuff box. Now, if you’ve learned something new today, why not share this article with a friend? Or better yet, leave a comment and let us know what you think. Who knows, maybe you’ll inspire someone else to dive deeper into the world of paper production!

Table of Contents:

- What Exactly is the Stuff Box?

- Why is the Stuff Box Important?

- How Does the Stuff Box Work?

- Key Components of the Stuff Box

- Types of Stuff Boxes

- Common Challenges in Using the Stuff Box

- Advancements in Stuff Box Technology

- The Role of the Stuff Box in Sustainable Paper Production

- Environmental Benefits of the Stuff Box

- Future Trends in the Stuff Box Industry